PE WPC Wooden grain profile extrusion machine line China Wood Plastic WPC profile machine manufacturer

- group name

- PP PE WPC Profile Machine

- Min Order

- 1 set

- brand name

- HEGU

- model

- SJMS65/132

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Mon, 28 Sep 2020 14:25:33 GMT

Paramtents

extruder SJMS65/132

Packging & Delivery

-

Min Order1 set

Briefing

automatic production,

high capacity:150-240kg/h

easy operate with reasonable design

make wood color directly

high capacity:150-240kg/h

easy operate with reasonable design

make wood color directly

Detailed

PE WPC Wooden grain profile extrusion machine line China Wood Plastic WPC profile machine manufacturer

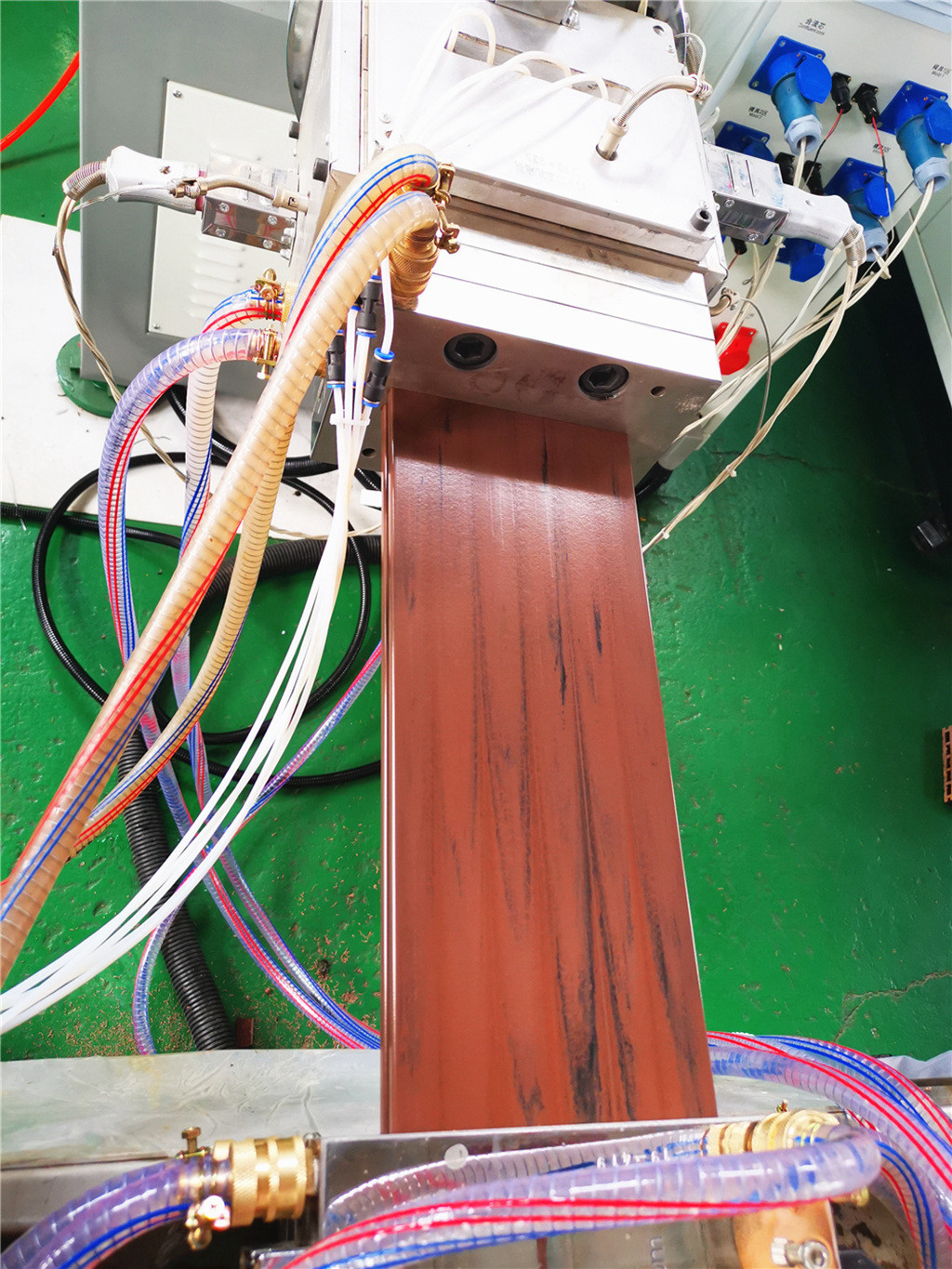

This PE WPC profile extrusion line is designed for making wooden color on the WPC profile surface without co-extrusion.

we will equip special designed color masterbatch feeding system for the extruder, so it will be able to make wooden color surface even by single extruder without co-extrusion.

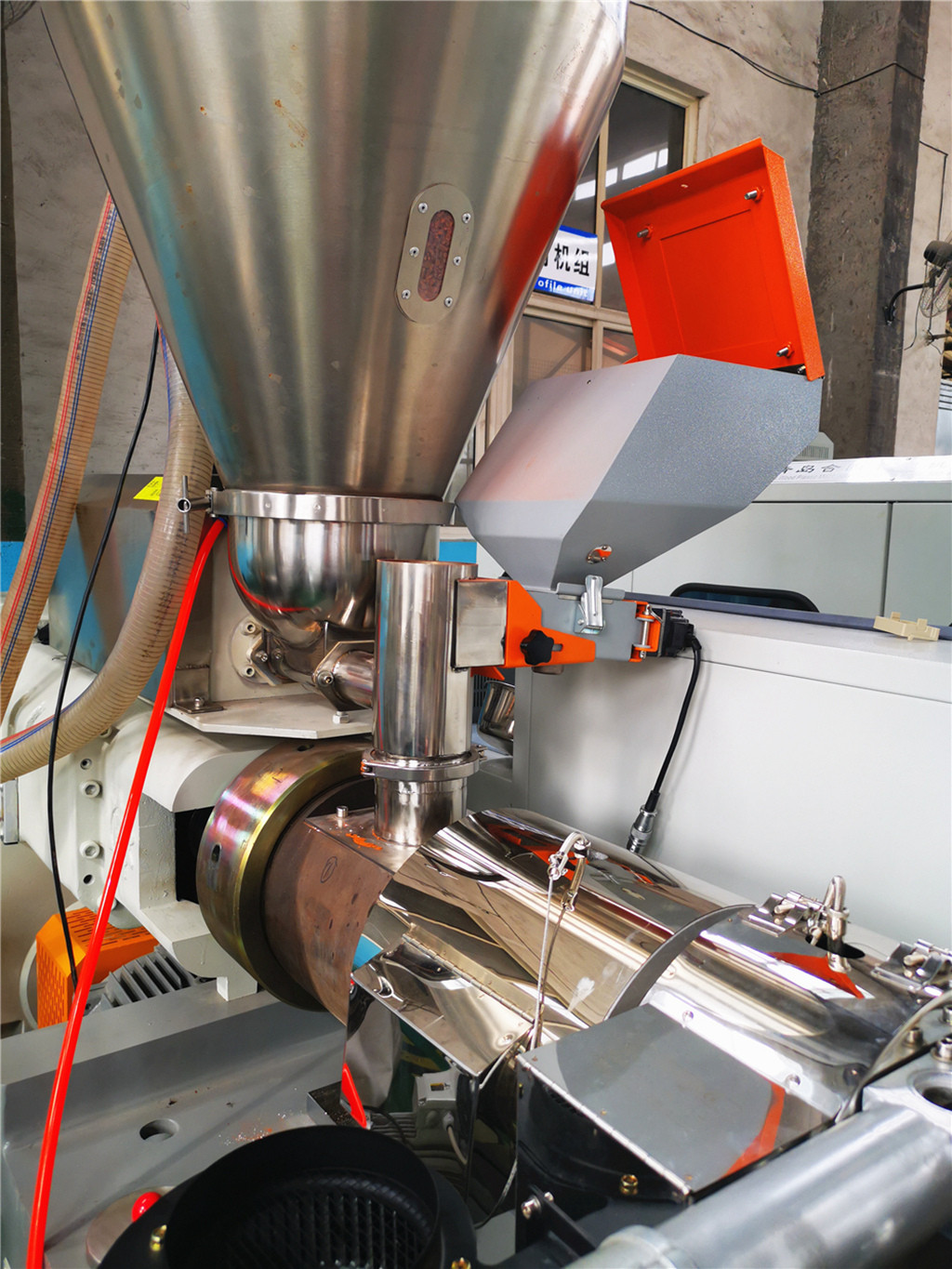

Detailed picture for PE WPC profile extrusion line

1, Conical double screw extruder: with automatic feeding device

2, color feeding hopper and WPC profile mold

3, Calibrator and water cooling system

4, Calibrating table for PE WPC profile extrusion line, 4-6meter

5, automatic cutting machine for PE WPC profile extrusion line

Advantage of this PE WPC profile extrusion line

1, automatic production from raw material feeding to final product

2, it can make wood color on the surface directly

3, easy to operate with reasonable machine design

4, high capacity by conical double screw

5, high quality machine with all good machine parts