WPC decking machine Wood Plastic WPC machine WPC profile Machine Manufacturer China Hegu WPC machinery

- group name

- PP PE WPC Profile Machine

- Min Order

- 1 set

- brand name

- HEGU

- model

- SJMS65/132

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Fri, 16 Oct 2020 15:42:12 GMT

Paramtents

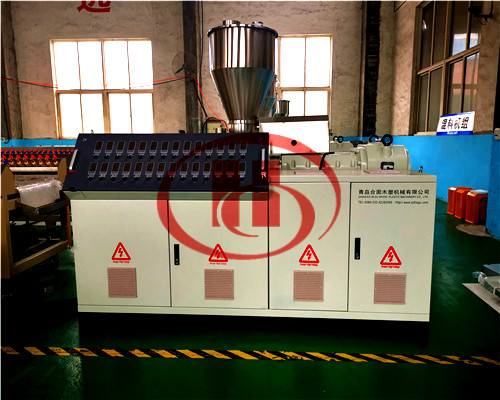

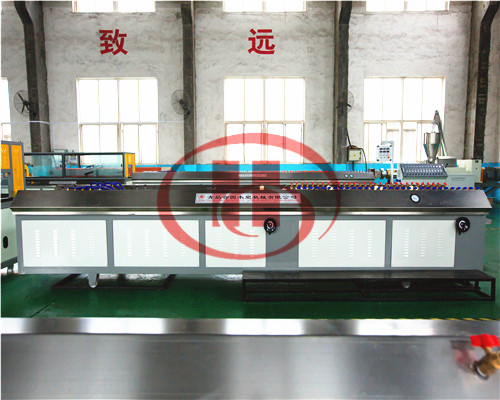

Product WPC decking extrusion line

Plastic Material recycled PP/PE

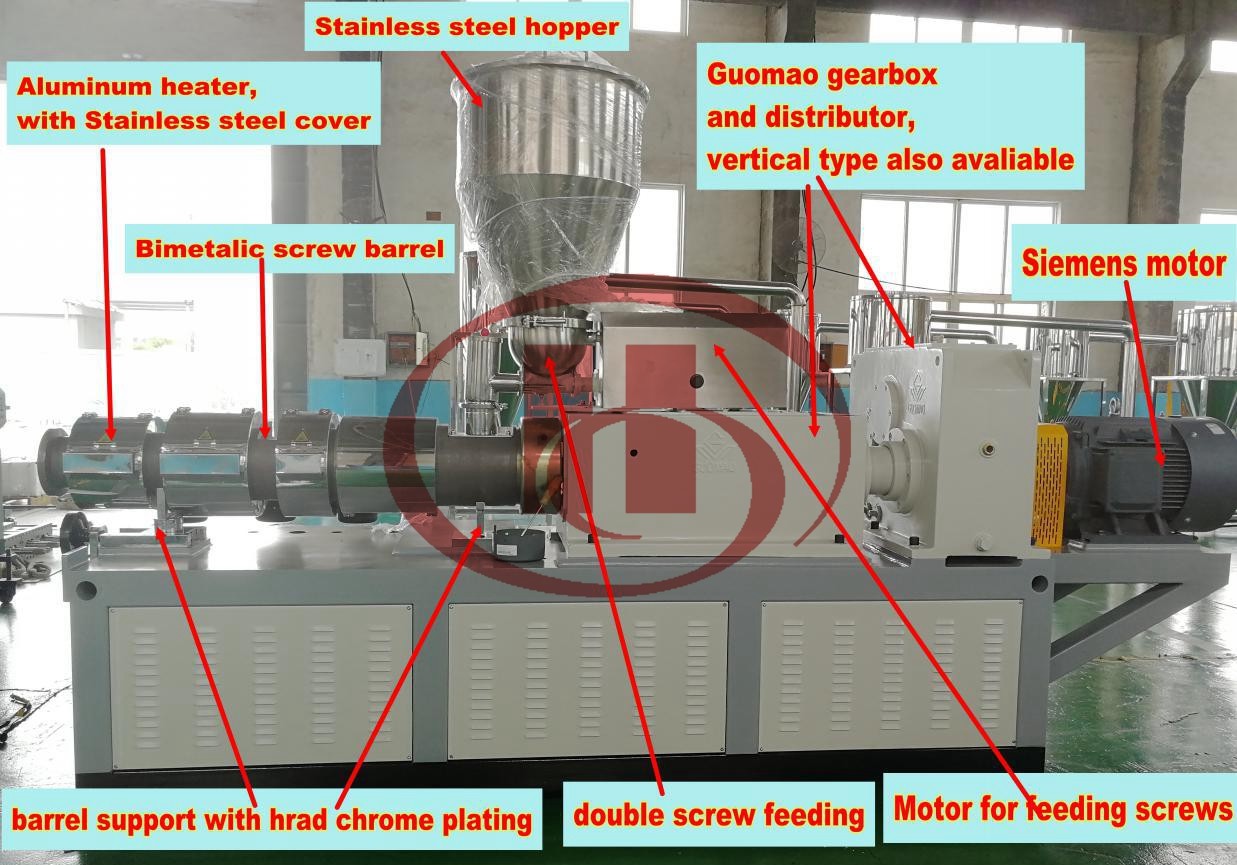

Motor Siemens

Inverter ABB

PLC Siemens

Pump Taiwan Yuanli

Gearbox Guoma

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

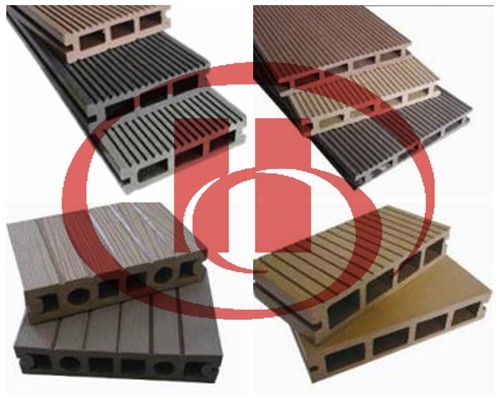

This

kind of wood-plastic are not only very similar with natural wood in

appearance and feel, but also have the same characteristics as wood of

excisable, planeable,sawable, unmatched grip,low bibulous rate, good

moisture resistance, mothproof,mildew resistance,good resistance to acid

and alkali,anti-corrosion, and it has the feature of fire resistance.

The products are non-toxic,non-polluting,environment-friendly and

save-energied, without formaldehyde, benzene and ammonia and other

harmful substances.

|

Material

|

WPC granules made by WPC granulation machine

|

|

Plastic percentage

|

20-30% recycled PP/PE

|

|

wood percentage

|

60-70% wood powder (made from rice husk,rice straw,cotton straw, wood sawdust, wood branch, wheat husk, wheat straw....)

|

|

Chemicals

|

5%-10% Chemicals: Coupling agent, PE wax, Stearic acid, CaCo3, pigments, Anti UV agent, Anti Oxygen agent

|

|

Moisture

|

less than 6%

|