The application of the PVC WPC foam board

pvc wpc foam board performance

1. Waterproof, flame retardant, acid and alkali resistance, mothproof, light weight, heat preservation, sound insulation and shock absorption

2. Same processing as wood, and the processing performance is far better than wood

3. Ideal substitute for wood, aluminum, composite sheet

4.The surface of the crust board is very smooth, high hardness, and it is not easy to have scratches.It is often used to make cabinets, furniture, etc.

2. Same processing as wood, and the processing performance is far better than wood

3. Ideal substitute for wood, aluminum, composite sheet

4.The surface of the crust board is very smooth, high hardness, and it is not easy to have scratches.It is often used to make cabinets, furniture, etc.

Application of the PVC foam board

PVC board sculpture

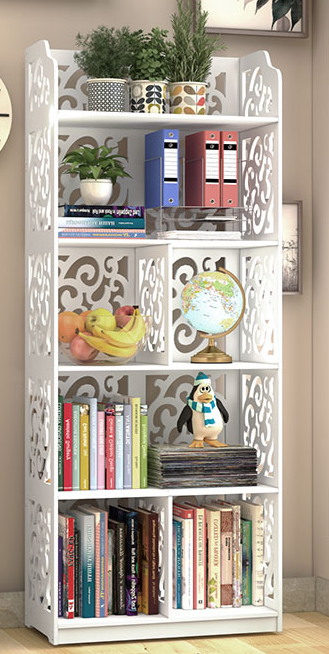

bookcase

bookcase

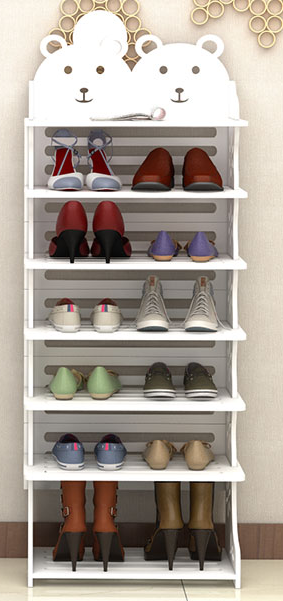

PVC foam board shoebox

pvc foam board cabinet

Furniture corner cabinet

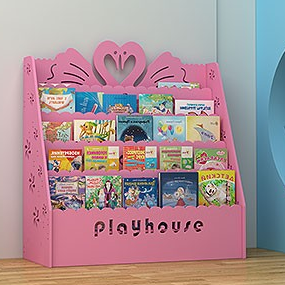

Foam board Children's bookcase

Foam board Flower stand

Foam board cupboard

Foam board forcer

PVC foam board is also called Chevron board and Andy board. Its chemical composition is Polyvinyl chloride, so it is also called foamed PVC board.

Widely used in passenger cars, train compartment ceilings, box cores, interior decoration panels, building exterior wall panels, interior decoration panels, office, residential, public place building compartments, commercial decorative frames, clean room panels , Ceiling panels, screen printing, computer lettering, advertising signs, display boards, logo photo albums and other industries, as well as chemical anticorrosive engineering, thermoformed parts, cold storage panels, special cold insulation projects, environmental protection molds, sports equipment, breeding materials , Beach moisture-proof facilities, water-resistant materials, art materials and various light partitions instead of glass ceilings.

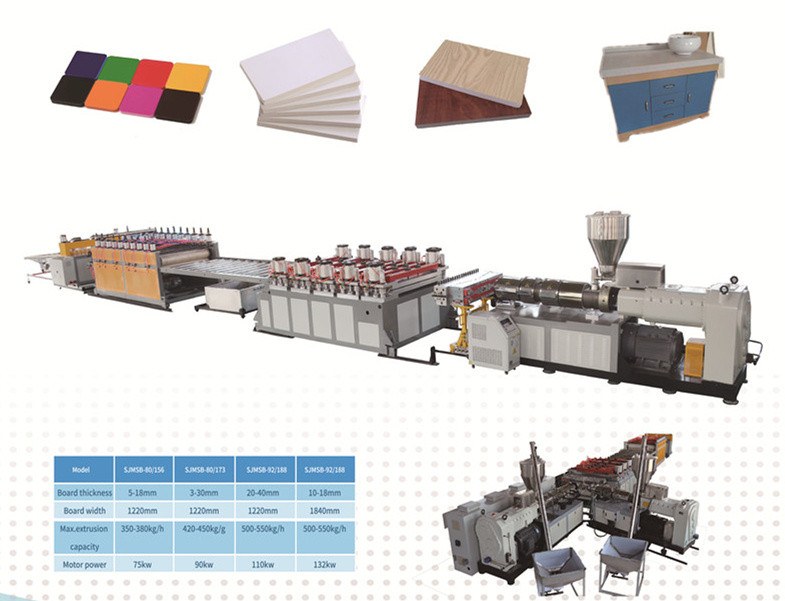

The machine for PVC WPC foam board

Hegu PVC WPC FOAM board making machine

SJMSB series PVC/WPC foam board production line can continuously produce PVC WPC foam board.This production line is composed of extruder, mould, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.The extruder adopts special screw. Calibrating platform equip width high efficiency cooling calibrator. Haul off machine adopts gear transmission to ensure uniform speed and high stabilize.The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.