What is the raw material for making PE WPC granules-wood plastic composite?

PE WPC production flow

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

Main raw material for the PE WPC granules

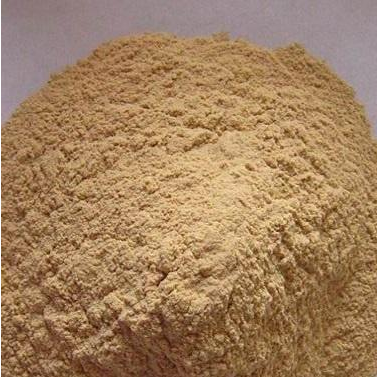

Wood powder

Crushing, milling and drying the wheat straw into 80-100 mesh powder

Washing, crushing ,drying the PP/PE plastic wastage into flakes, the flakes shall be used for WPC production directly.

Special wood plastic additives for PE / antioxidant

Appearance: white powder

Basic characteristics:

Chemical name Tetra [β- (3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, this product is a good antioxidant

Basic characteristics:

Chemical name Tetra [β- (3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, this product is a good antioxidant

PE Wood Plastic Auxiliary / UV Resistant UV531

The UV-531 ,chemical name is 2-hydroxy-4 n-octyloxybenzophenone. It is an effective anti-aging additive with excellent performance. It can absorb 240-340 nanometers of ultraviolet light. Poisonous, good compatibility, low migration, easy to process and so on. It has a large protective effect on the polymer and helps reduce color, while delaying yellowing and blocking physical property loss.

PE wood plastic additives / compatibilizer (coupling agent)

1. The wood-plastic compatibilizer is a fatty acid amide graft modified product.

2. Control viscosity and improve demolding

3. Improve the dispersion of mixed uniform filler

4. Improve internal flow of profiles

5. Eliminate edge tearing

6. Significantly increase extrusion speed

7. Reduce equipment torque and temperature, protect equipment and extend equipment life

2. Control viscosity and improve demolding

3. Improve the dispersion of mixed uniform filler

4. Improve internal flow of profiles

5. Eliminate edge tearing

6. Significantly increase extrusion speed

7. Reduce equipment torque and temperature, protect equipment and extend equipment life

pe Wood Plastic Processing Aid PE Lubricant / Zinc Stearate

Calcium stearate is white, fine powder, slightly soluble in hot ethanol. It is decomposed into stearic acid and the corresponding calcium salt by strong acid, and it is easy to absorb moisture in the air.

Zinc stearate is a light white powder with a specific gravity of 1.095. It has a greasy feel, is insoluble in water, and is soluble in organic solvents such as hot ethanol, benzene and turpentine. It will decompose into stearic acid and the corresponding zinc salt in the presence of strong acids. The product is hygroscopic.

Zinc stearate is a light white powder with a specific gravity of 1.095. It has a greasy feel, is insoluble in water, and is soluble in organic solvents such as hot ethanol, benzene and turpentine. It will decompose into stearic acid and the corresponding zinc salt in the presence of strong acids. The product is hygroscopic.

PE wood plastic color powder series iron red mother powder

Iron oxide red is an inorganic color pigment with fine powder. It has high hiding power, strong tinting power, and good dispersibility. Its light resistance and weather resistance are very good.

Polyethylene wax _ PE wax

PE wax, also known as polymer wax for short. Because of its excellent cold resistance, heat resistance, chemical resistance and abrasion resistance, it has been widely used. It can improve the fluidity of polyethylene, polypropylene, ABS and the release properties of polymethyl methacrylate and polycarbonate. Compared with PVC and other external lubricants, polyethylene wax has a stronger internal lubrication effect.