What is better between Wood-Plastic WPC products and Anti-corrosion wood?

What is better between Wood-Plastic Composite WPC products and Anti-corrosion wood?

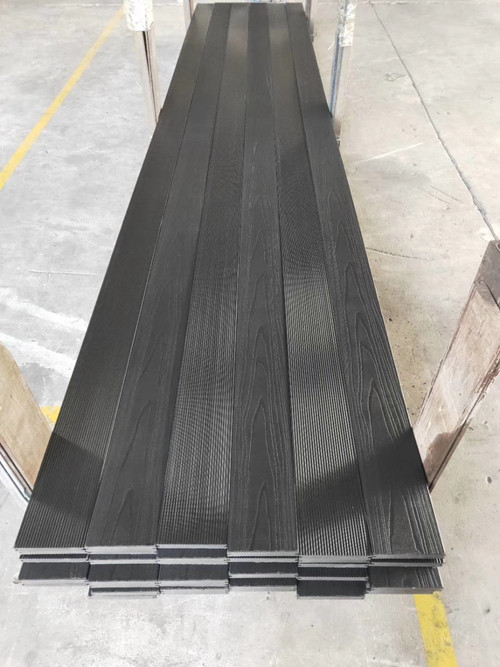

Anti-corrosion wood is a kind of anti-corrosion, moisture-proof, anti-fungal, anti-insect, anti-mildew and waterproof property of ordinary wood after artificial addition of chemical preservative. Wood-plastic composite products are high-density fibers and HDPE materials that are made into wood-plastic composite materials through granulation equipment, and then extruded into production groups to form wood-plastic sheets.

1. The size of the plastic wood profile can be customized at will, and the loss is less than that of the anti-corrosion wood.

Under the same construction area or volume, plastic wood has less loss than anti-corrosion wood. Because plastic wood is a profile, it can produce materials that meet the required length, width and thickness according to the actual size requirements of the landscape project. The length of the preservative wood is stipulated to be dead, generally 2 meters, 3 meters, 4 meters.

2, plastic wood can be under the same construction conditions, can win less.

To make an analogy, the outdoor floor is generally paved, and in the case of wood, a thickness of about 45 mm is required. For plastic wood, only 25mm thick material is needed, and its strength exceeds 45mm anti-corrosion wood. In other words, if the use of wood is 1 cubic meter, then the plastic wood only needs about 0.5 cubic meters.

3, plastic wood is a profile, hollow specifications. Save a lot of material.

Aluminum alloy doors and windows can be popularized so quickly, because it is a hollow profile, if it is solid, then the price is incredibly high. The plastic wood hollow part is cheaper, although it is not as high as aluminum alloy, but it is also objective. Hollow can not only reduce weight and increase strength. Plastic wood can be hollow, and anti-corrosion wood is impossible.

4. The surface of the plastic wood does not need to be painted.

Generally, the wood surface is painted or painted with water-based paint after the construction of the anti-corrosion wood or the construction process.

5, plastic wood products can be life-long maintenance-free.

Anti-corrosion wood is usually required to be maintained or painted in one year due to ambient temperature and humidity and solar ultraviolet radiation. And plastic wood is maintenance-free for life! In the long run, the cost of plastic wood is far below that of preservative wood products.

6, the service life of plastic wood, generally can reach 8-9 times of ordinary wood. Foreign data shows that plastic wood can be used for 40-80 years.

7. Wood-plastic products are recycled green building materials. The dismantled wood-plastics can be recycled and reused, reducing resource consumption and meeting the low-carbon economy.